SPECTROMART SCIENTIFIC & LABORATORY EQUIPMENT TRADING L.L.C.

PRODUCTS

Spectrometers – Atomic Spark Emission

OPTICAL EMISSION SPECTROMETRY (OES)

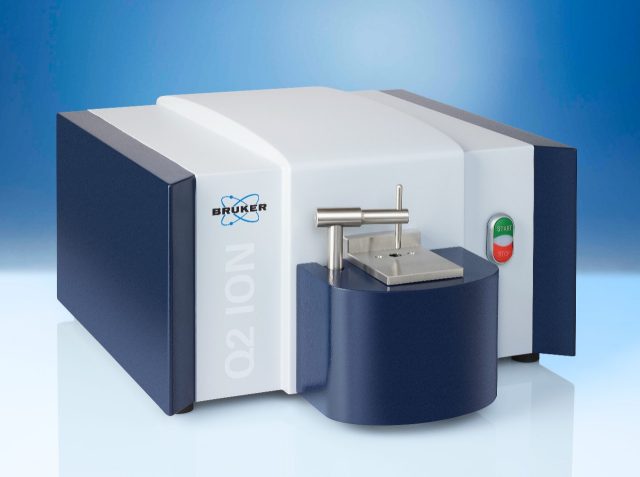

Q2 ION

Ultra-Compact, portable Metals Analyzer

The new generation of spark spectrometer Q2 ION elevates metal analysis into new levels of simplicity and ease-of-use. Today it is one of the smallest and lightest ultra-compact spark emission spectrometer for metal analysis available. It is a versatile multi-matrix system for comprehensive incoming material inspection and quality assurance of metal alloys. Its primary applications and metal matrices include copper, aluminum and iron at smaller foundries, inspection companies, metal recycling and metal fabricators. An affordable price and exceptional low operational costs make this spectrometer the ideal tool for smaller and medium-size businesses.

Key Benefits:

- Dedicated Analytical Solution Packages (ASP) for your analytical tasks. ASPs for the Q2 ION are available per base and include elements and calibrations for all alloy groups. In no time at all, you receive reliable, complete analytical results.

- Patented flat field optics with AAC and array detectors with ClearSpectrum® technology provide maximum stability best-in-class analytical performance.

- Nearly maintenance-free spark stand with low argon consumption for lowest operational costs.

- ELEMENTAL.SUITE delivers highest functionality combined with ease-of-use for information @ your fingertips.

OPTICAL EMISSION SPECTROMETRY (OES)

Q4 POLO

Compact multi-chip Spark Spectrometer

Numerous innovations have been introduced in the Q4 POLO to create a spark spectrometer that is second to none. In addition to superior analytical performance for a full range of elements, the Q4 POLO enables applications previously not addressable by such compact instruments.

Just as impressive as the results achieved by the Q4 POLO is its incredible long-term stability. The absence of thermal- and contamination-based drifts reduces the need for cleaning and recalibrations, leading to stable results around the clock.

The new Q4 POLO is the ready-to-analyze solution from day one, covering all relevant elements and wide concentration ranges. Each base metal package includes all dedicated alloy groups, calibrations, and standardization samples. At the same time, the Q4 POLO provides high uptime, low maintenance, and hassle-free operation.

Key Benefits:

- MultiVision™ optics with electromagnetic light junction covering the full elemental range with superior performance and small footprint

- AAC™ and ArgonShield™ result in incredible long-term stability without increasing argon gas consumption

- The new active sensing SmartSpark™ source is fully digital and equipped with detection of non-energetic discharges for increased precision and long-term stability

- ELEMENTAL.SUITE delivers highest functionality combined with ease-of-use for information @ your fingertips.

OPTICAL EMISSION SPECTROMETRY (OES)

Q4 TASMAN Series 2

Advanced multi-chip benchtop spectrometer

Our engineers took every opportunity to further improve the analytical performance in the new Q4 TASMAN Series 2. The analytical range of the Q4 TASMAN Series 2 has been extended for many elements, and new element sets enable the analysis of new alloy types. Addressing the entire metals market, dedicated Analytical Solution Packages (ASPs) are available for all ten common metal bases: Fe, Al, Cu, Ni, Co, Pb, Sn, Zn, Mg, and Ti.. These ASPs include full element sets, calibrations, alloy groups, and standardization samples. ASPs provide analytical performance that’s precisely tuned for the metals world – and its future demands.

Key Benefits:

- MultiVision™- the innovative optics concept delivers the optimal solution for your applications, in the most economical way.

- SmartSpark™ – the further optimized Digital Spark Source delivers improved analytical precision and shorter time-to-result.

- Low Maintanance spark stand with improved co-axial argon flow and pneumatic sample clamp for hassle-free operation.

- ELEMENTAL.SUITE delivers highest functionality combined with ease-of-use for information @ your fingertips.

OPTICAL EMISSION SPECTROMETRY (OES)

Q8 MAGELLAN

High-End Optical Emission Spectrometer for Metal Analysis

The new generation of the Q8 MAGELLAN spectrometer is setting new standards with respect to stability, flexibility, ease-of-use and analytical functionality for the elemental analysis of metals. Each Q8 MAGELLAN is tailor made to match your current and future requirements by an optimal selection from >200 available analytical channels: single or multi-base applications, trace analysis or alloys, the Q8 MAGELLAN can be configured to master virtually any metal analysis task.

Key Benefits:

- 100% PMT-based performance supported by a digital plasma generator for unlimited time resolution incl. SSE and inclusion analysis

- High-vacuum optics ensures optimal performance without argon purge

- Heavy-Duty, low maintenance spark-stand with co-axial argon flow

- Automatic sample clamp ensures fast and reliable one-button operation

- ArgonStopTM means no argon consumption during breaks with reduced start-up times and improved analytical performance on small samples and thin wires

- True factory calibration with reference materials, evaluated by an expert to ensure highest accuracy and analytical quality

Glow Discharge Spectrometers

GDA 150 HR

Powerful and flexible instruments for daily quality control tasks

The GDA 150 HR glow discharge spectrometer is a robust, temperature-stabilized CCD spectrometer developed for elemental depth profile analysis and bulk elemental analysis in the production sector. The GDA 150 HR is optmized to meet the requirements of small and medium sized companies.

The instrument can be used e.g. for the following applications:

- to inspect the surfaces after diffusion processes

- to examine galvanic coating processes

- to analyze hard material coatings via PVD or CVD

- to assess hot dip galvanizing as well as other kinds of galvanizing

- to determine the elemental concentration in layers and bulk material

The GDA 150 HR is suitable for all electrically conductive matrices, as well as for light elements such as C, N and H (and optionally also O).

Due to the simple device operation and high speed of an analysis cycle it is possible to intervene quickly in the production process to correct any possible errors – a crucial advantage over conventional methods like metallographic investigations which need relatively long preparation time.

Advantage of the High Resolution SPECTRUMA CCD optics:

Flexibility in the selection of the element channels

Glow Discharge Spectrometers

GDA 650 HR

Powerful and flexible instruments for daily quality control tasks

With the development of the GDA 650 HR the evolution of CCD glow discharge analyzers has reached the next level.

The GDA 650 HR uses the latest CCD technology in optics, which combines high resolution and sensitivity. By using the direct light path without transmission losses best detection limits are guaranteed. It is the ideal solution for customers who want precision and flexibility.

To avoid hydrocarbon contaminations the GDA 650 HR is equipped with a scroll pump. Using the installed Radio Frequency (RF) Glow Discharge Lamp, the GDA 650 HR is unexcelled in analyzing non-conductive materials such as ceramics, glass and paint layers, using the standard lamp set or a specially designed version for the universal sample unit (USU).

The instrument can be used e.g. for the following applications:

- to analyze incoming base material

- for depth profile in the production area

- to inspect surfaces after diffusion processes

- to examine galvanic coating processes

- to analyze hard material coatings via PVD or CVD

- to assess hot dip galvanizing as well as other kinds of galvanizing

- to determine the elemental concentration in layers and bulk material

- to analyze CIGS thin film solar cells

- to analyze light elements, such as O, C, N and H

- to analyze non-flat surfaces, such as pipes or spheres by using the USU

Due to the simple device operation and high speed of an analysis cycle it is possible to intervene quickly in the production process to correct any possible errors – a decisive advantage over conventional methods like metallographic investigations which need relatively long preparation time.

Advantages of the High Resolution SPECTRUMA CCD optics:

Flexibility in the selection of the element channels